High Reliability NTC Thermistor for Automotive Water Temperature Sensor

Within the automotive thermal management system, the water temperature sensor serves as the “thermoregulation expert.” By continuously monitoring changes in the temperature of the coolant, it establishes a critical safeguard for the vehicle’s safe operation. Utilizing a highly reliable NTC thermistor as its core sensing element, the device is deployed in areas with high heat loads, such as air conditioning liquid cooling pipelines and engine coolant outlets. This enables closed-loop control of the powertrain operating temperature.

Excessively high engine coolant temperature signals that the engine is operating at the edge of a dangerous condition. Continuing to drive under such circumstances can impair engine performance, accelerate internal component wear, and, in severe cases, even lead to smoke or fire in the engine compartment. Consequently, temperature monitoring plays a crucial role in ensuring the safety of automotive operations. A detailed analysis of its structure, application scenarios, and more follows below:

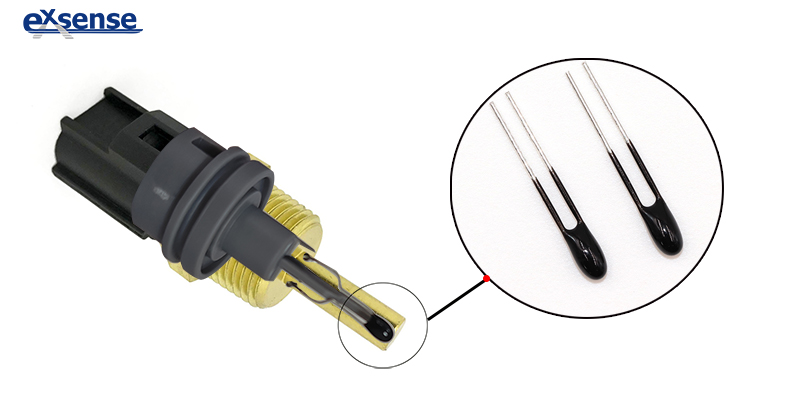

Ⅰ. Structure of the Automotive Water Temperature Sensor

The automotive water temperature sensor primarily consists of an NTC thermistor, conductive pins, insulating spacer, metal housing, and riveting components. The thermistor is mounted at the tip of the metal base shell. The metal housing directly contacts the coolant, providing waterproofing.

Ⅱ.Application Scenarios of the NTC Water Temperature Sensor

Leveraging its sensitive temperature detection characteristics, the NTC water temperature sensor plays a key role in ensuring the stable operation of systems within air conditioning liquid cooling pipelines and engine coolant systems. Specific application scenarios are analyzed below:

- Air Conditioning Liquid Cooling Pipelines

- Evaporator Antifreeze Control:NTC thermistors installed on the A/C evaporator pipes monitor the refrigerant temperature in real time. When the temperature approaches freezing point (e.g., 1°C), the NTC transmits data to the control system. This automatically adjusts the opening degree of the electronic expansion valve, reducing refrigerant flow. If the temperature drops to 0°C, the system immediately initiates a defrost cycle or halts compressor operation to prevent ice formation on the evaporator surface, avoiding reduced heat exchange efficiency and equipment damage.

- Condenser Heat Dissipation Optimization:NTC thermistors sensor positioned on condenser pipes monitor refrigerant temperature. Temperatures exceeding the normal range (e.g., 80°C) indicate inadequate heat dissipation. The NTC then triggers the cooling fan to increase speed or activates auxiliary cooling devices to enhance heat dissipation capacity. If the temperature continues to rise to a critical threshold (e.g., 95°C), the system automatically reduces compressor power or shuts it down to prevent high-pressure line rupture.

- Chilled Water Constant Temperature Regulation:In central air conditioning chilled water pipelines, NTC thermistors sensor monitor the supply and return water temperatures (typically supply: 7°C, return: 12°C). Based on this data, the system automatically adjusts the water pump speed and the number of operating chiller units. This ensures stable chilled water temperature, enables on-demand cooling and improves energy efficiency.

- Engine Coolant Outlet

- Cold Start Preheating & Freeze Protection:In low-temperature environments, the NTC thermistor monitors engine coolant temperature. If the temperature falls below -10°C, it signals the Engine Control Unit (ECU). The ECU then delays ignition advance angle and reduces engine load to prevent startup wear caused by thick oil and poor coolant flow. Simultaneously, if the coolant temperature nears freezing, the system activates electric heaters or initiates antifreeze circulation to prevent coolant freezing and engine block cracking.

- Temperature Monitoring & Overheat Warning:During vehicle operation, the NTC prode monitors coolant temperature in real-time (normal operating range: 80-105°C). If the temperature exceeds 110°C, the NTC immediately triggers an ECU alert, illuminating a warning light on the instrument panel to notify the driver. Should the temperature continue to rise to 120°C, the system automatically reduces engine power or even forces a shutdown to prevent severe engine damage, such as cylinder scoring or head gasket failure, due to overheating.

- Cooling System Intelligent Regulation:The NTC thermistor transmits coolant temperature signals to the ECU. Based on this, the ECU controls the electronic water pump speed, thermostat operation, and radiator fan activation. This ensures the engine consistently operates within its optimal temperature range.

Given the water temperature sensor’s role as a core component in thermal management, the EXSENSE’s VT Series thermistors are highly recommended. This product line utilizes high-precision NTC thermistors in its construction, featuring temperature measurement accuracy within ±1°C and a broad operating range of -40°C to 150°C. It maintains stable resistance characteristics even under harsh operating conditions, establishing a dual protective barrier for both vehicle operational safety and passenger safety.

Conclusion: Through continuous technological iteration, automotive water temperature sensors are evolving from simple temperature-sensing components into intelligent thermal management terminals. They play an indispensable role in enhancing powertrain durability and optimizing automotive thermal management and temperature control.