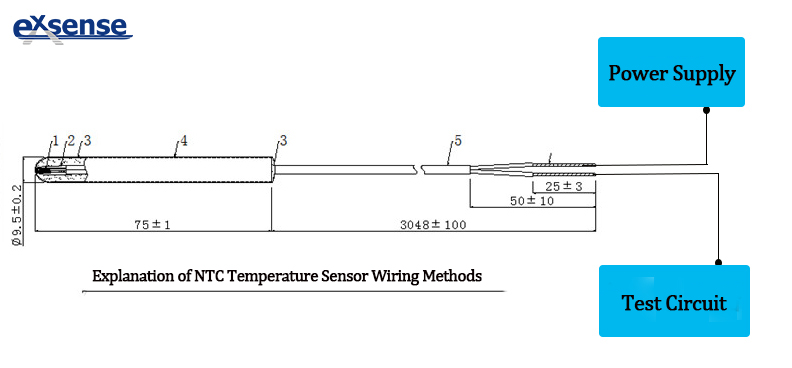

Detailed explanation of NTC Temperature Sensor Wiring Methods

The NTC (Negative Temperature Coefficient) temperature sensor, a classic thermistor semiconductor component, exhibits a unique physical characteristic where its resistance decreases exponentially with rising temperature. This property grants it distinct application value in modern industrial fields, particularly in scenarios demanding stringent temperature control. These include thermal management of the three-electric systems in new energy vehicles, temperature balancing in energy storage battery packs, temperature compensation in consumer electronics, and overheating protection in office automation/printing equipment. Below, we introduce standard wiring methods and key considerations during the wiring process.

Ⅰ. Common Wiring Methods for NTC Temperature Sensors

- 1.Identify Sensor Pins

NTC temperature sensors typically have two or three pins.

Two-pin sensors: Connect to the power supply and measurement circuit.

Three-pin sensors: The third pin (if present) is usually for grounding or specialized functions.

- Connect Power Supply and Measurement Circuit

Connect the two main pins of the NTC sensor to the power supply‘s positive and negative terminals or the measurement circuit‘s input terminals.

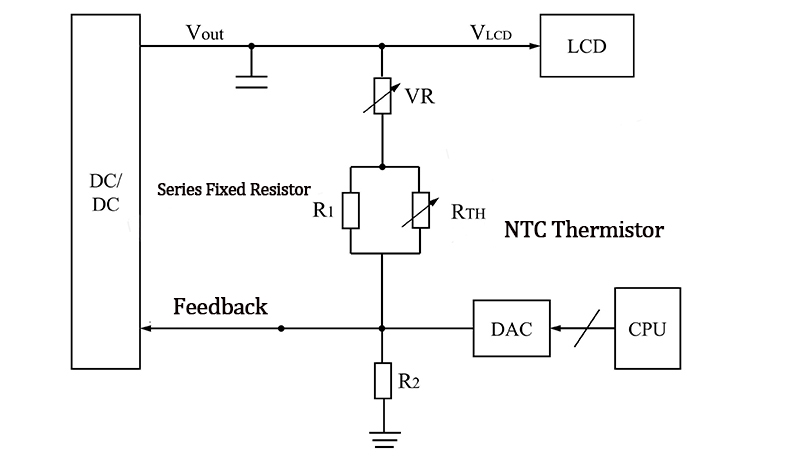

In some applications, a series resistor may be required to form a voltage divider circuit, enabling measurement of the NTC‘s resistance changes.

Ⅱ.Wiring Precautions

- Pin Polarity

Ensure correct polarity during wiring. Reversed connections may lead to measurement inaccuracies or sensor damage.

- Wire Selection

Use wires of moderate length and uniform diameter to minimize line impedance and signal attenuation.

Ensure wires have excellent insulation to prevent short circuits or leakage.

- Temperature Range

Select an NTC sensor with a temperature range that matches the application‘s operating conditions. Exceeding the sensor‘s maximum temperature tolerance may damage the device or components.

- Filtering and Decoupling

In noise-sensitive applications, filter or decoupling capacitors are added to suppress interference and improve measurement accuracy.

- Verification and Calibration

After wiring, perform reliability and sensitivity tests on the NTC sensor.

Calibrate using a standard temperature source or reference measurement equipment to ensure accuracy.

Summary

The wiring method for NTC temperature sensors should align with the specific application scenario and measurement requirements. During installation, critical factors include pin polarity, wire selection, temperature range compliance, noise suppression, and post-wiring calibration. Proper wiring ensures optimal sensor performance, enabling precise temperature monitoring and control across diverse applications.